Alloy Plate/Sheet Inconel 600 601 625 X-750 718 825 Inconel Plate Sheet

Basic Info

| Model NO. | Inconel sheet |

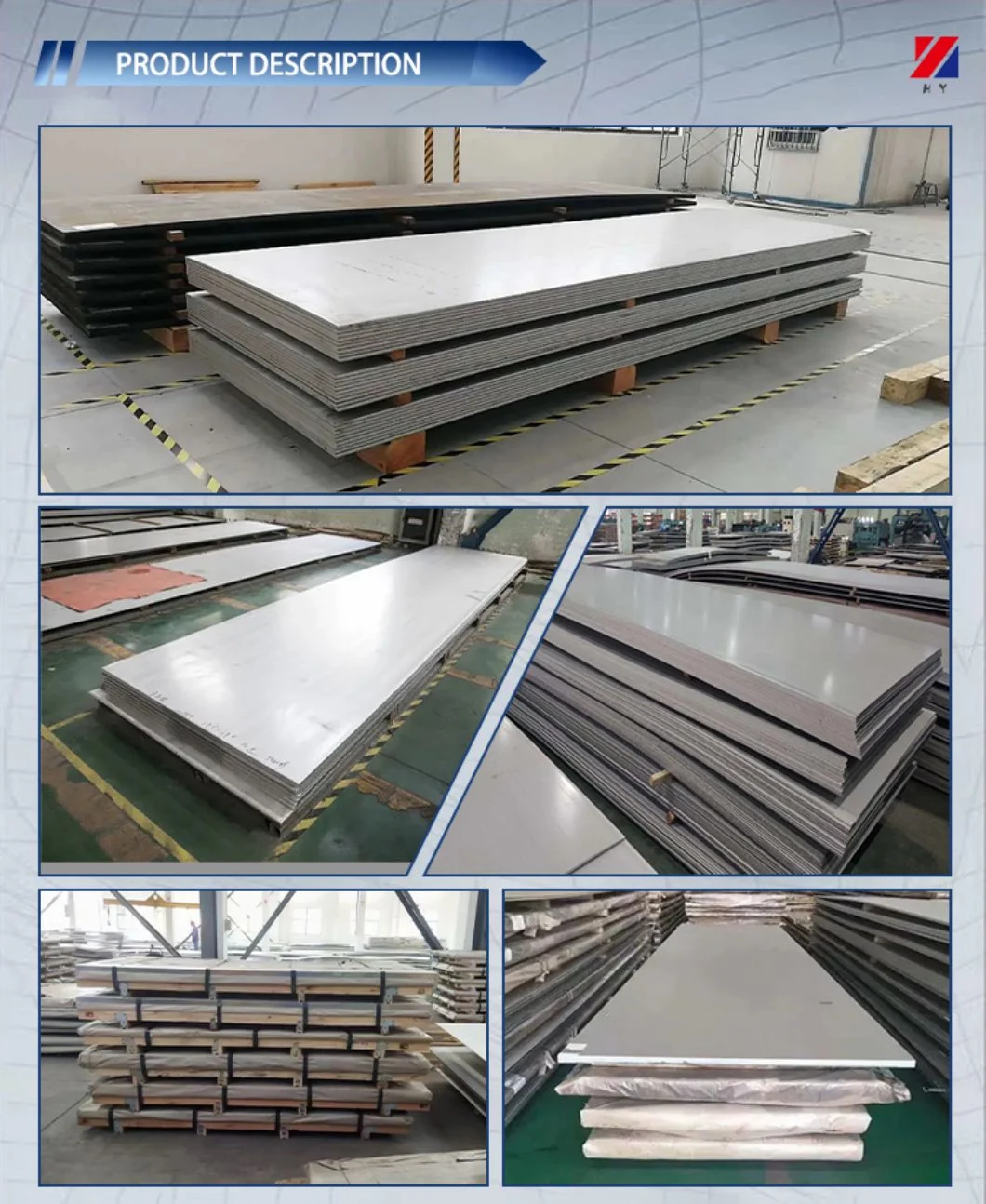

| Thick | 1-200mm or as Cusomers Requirements |

| Width | 1000-2440mm or as Cusomers Requirements |

| Length | as Cusomers Requirements |

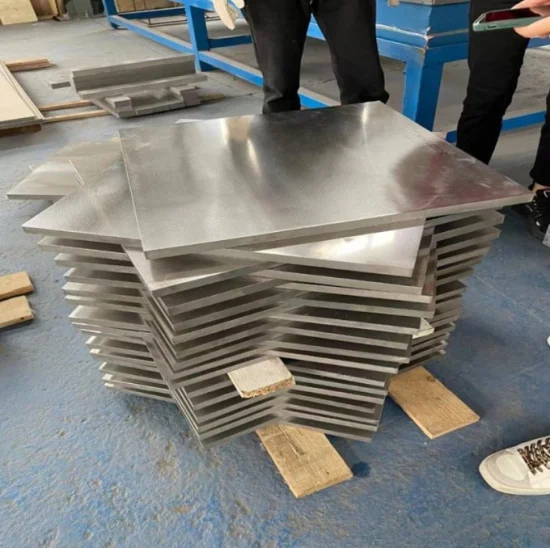

| Transport Package | Standard Packing or OEM |

| Specification | as cusomers requirements |

| Trademark | HY |

| Origin | Cn |

| Production Capacity | 500000 Ton Per Year |

Product Description

Characteristic:1.Has good resistance to reduction, oxidation, and nitriding medium corrosion2.Good stress corrosion cracking resistance at room temperature and high temperature3.Good resistance to dry chlorine and hydrogen chloride gas corrosion4.Good mechanical properties at sub-zero, room temperature and high temperature5.Due to its good creep rupture strength for the control of carbon content and grain size, it is recommended to be used in a working environment above 700 ° C.

Application:1. Thermowell in an aggressive atmosphere2. Vinyl chloride monomer production: resistant to chlorine, hydrogen chloride, oxidation and carbonation corrosion3. Oxidation of uranium to hexafluoride: resistance to hydrogen fluoride corrosion4. Production and use of corrosive alkali metals, especially the environment where sulfides are used5. Preparation of titanium dioxide by chlorine6. Production of organic or inorganic chlorides and fluorides: resistant to chlorine and fluorine gas corrosion7. Nuclear reactor8. Curved neck flasks and components in heat treatment furnaces, especially in carbonizing and nitriding atmospheres

Remark:

1. We use rolling process.

2. The thickness dimensional tolerance is ±0.05mm.

Technical Specification:

| Inconel | Element(% by mass) | ||||||||||||||

| Ni | Cr | Fe | Mo | Nb&Ta | Co | Mn | Cu | Al | Ti | Si | C | S | P | B | |

| 600 | ≥72.0 | 14.0-17.0 | 6.0-10.0 | ≤1.0 | ≤0.5 | ≤0.5 | ≤0.15 | ≤0.015 | |||||||

| 617 | 44.2-61.0 | 20.0-24.0 | ≤3.0 | 8.0-10.0 | 10.0-15.0 | ≤0.5 | ≤0.5 | 0.8-1.5 | ≤0.6 | ≤0.5 | 0.05-0.15 | ≤0.015 | ≤0.015 | ≤0.006 | |

| 625 | ≥58.0 | 20.0-23.0 | ≤5.0 | 8.0-10.0 | 3.15-4.15 | ≤1.0 | ≤0.5 | ≤0.4 | ≤0.4 | ≤0.5 | ≤0.015 | ≤0.015 | |||

| 690 | 59.5 | 30 | 9.2 | 0.35 | 0.01 | 0.02 | 0.35 | 0.019 | 0.003 | ||||||

| 718 | 50.0-55.0 | 17.0-21.0 | balance | 2.8-3.3 | 4.75-5.5 | ≤1.0 | ≤0.35 | ≤0.3 | 0.65-1.15 | ≤0.35 | ≤0.08 | ≤0.015 | ≤0.015 | ≤0.06 | |

| X-750 | 70 | 14.0-17.0 | 5.0-9.0 | 0.7-1.2 | 1 | 1 | 0.5 | 0.4-1.0 | 2.25-2.75 | 0.5 | 0.08 | 0.01 | |||

| Composition (%) | Ni +Co | Cu | Mn | C | Si | S |

| N6 | ≥99.5 | ≤0.06 | ≤0.05 | ≤0.10 | ≤0.10 | ≤0.005 |

A: Can provide small samples for free. Customized sample takes 5-7 days.

Q2: How about the delivery time?

A: Small trial order takes 5-7 days. Container order need 15-20 days.

Q3: Do you have any protection when packing?

A: Cover with PE film , wrap with waterproof paper, pack with wooden plate,belt by steel strip, fasten on pallet.

Q4: What's the terms of delivery?

A: EXW, FOB, CFR, CIF, DDP

Q5: How many countries you already exported ?

A: Exported to more than 23 countries mainly from South America(Chile, Brazil etc), Russia, UK, Kuwait, SAUDI ARAB, UAE, Singapore, Turkey, Australia,Egypt, South Africa etc.