Customized Forged Steel Ball Sphere Spare Kits Tungsten Carbide Coated Ball Inconel 625 Overlay Cladding Ball Nickel Painting Fabricated Valve Ball Machining

Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 1500.000kg Lead Time 20 days ;

Basic Info

| Model NO. | VP |

| Certification | CCC, RoHS, ISO, CE |

| Surface Treatment | Polishing, Sand Blast, Chrome Plating, Nickel Plating, Tungsten Carbide Coated, Stellite Coated |

| Temperature | High Temperature |

| Pressure | High Pressure |

| Material | Stainless Steel |

| Type | Two-Way |

| Model | Trunnion Ball,Floating Ball,Three Way Ball |

| Ball | Solid Ball, Hollow Ball,Long Stem Ball |

| Material Process | Forged |

| Base Material | A105,A350 Lf, 304,316,F51,F53,F55,F6a |

| Roundness | 0.01-0.04mm |

| Coating | Enp,Chrome Plating,Tungsten Carbide,Chrome Carbide |

| Coaxiality | 0.05-0.10mm |

| Hardness | Hb120-350, HRC20-120 |

| Finish Process | Grinding, Polishing |

| Special Process | Lapping |

| Weld Overlay | Inconel 625 Overlay, Monel,Stellite Overlay |

| Design | as Per Drawings, Customized |

| Transport Package | Plastic+Wooden Case |

| Specification | 1500*1500*2000mm |

| Trademark | O. E. M or AEA Brand |

| Origin | China |

| HS Code | 8481 |

| Production Capacity | 5000000 PCS/Year |

Packaging & Delivery

Package size per unit product 100.00cm * 100.00cm * 100.00cm Gross weight per unit product 1500.000kg Lead Time 20 days (1 - 1 Pieces)To be negotiated ( > 1 Pieces)

Product Description

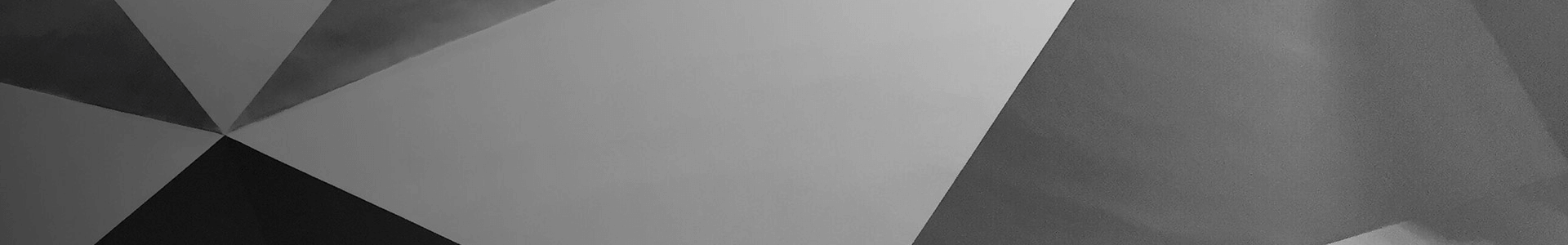

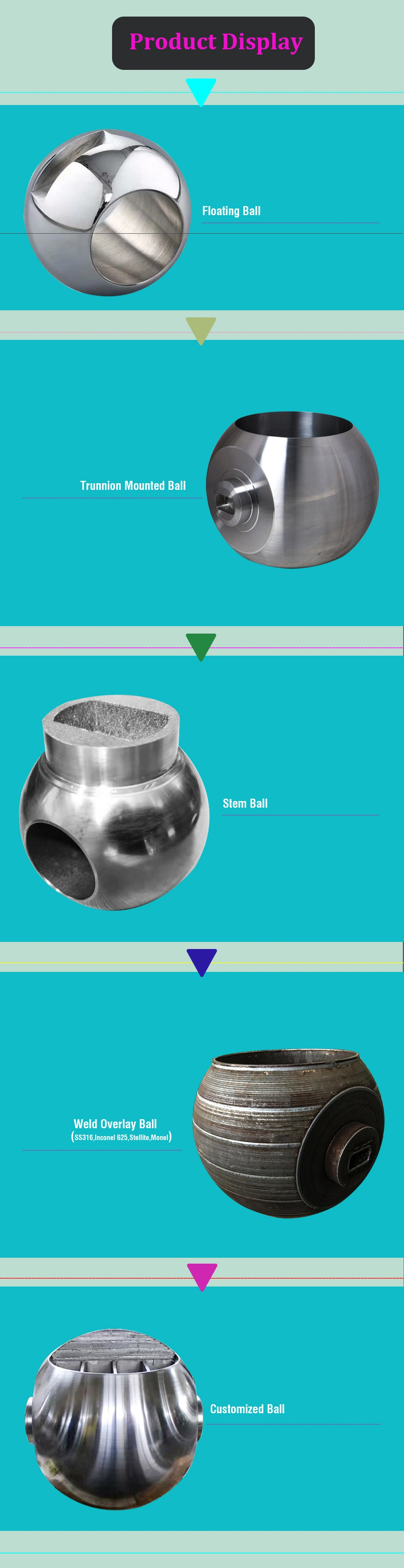

AEA Customized Forged Steel Balls for Ball ValvesProduct Name: Steel ball for ball valves, Valve SphereProduct Type: trunnion ball, floating ball, spigot mounted, stem ball, three way ball, segmented ball, V type ball,Size Range:Ball for floating ball valve: NPS 1- 10 InchesBall for trunnion ball valve: NPS 1- 60 InchesPressure Rating: ANSI 150~2500Lbs, JIS 5K~30K, PN16~420Sphericity: ØNPS 1- 12 Inches: Minimum 20 micron (ìm ) ØNPS 12- 60 Inches: Minimum 30 micron (ìm )Product Standard: ANSI, UNI, DIN, JIS, EN. or as customers' drawingsBase Materials:ØCarbon Steel: ASTM A105,ASTM A350 LF2 LF3,LC1,LC2,LC3,ØStainless Steel: ASTM A182 F304,F304L,F316,F316L,F317,F317L,F321,F51,F53,F6a/AISI 410,420ØAlloy Steel: A564 630(17-4PH), Monel, Inconel…ØBrass/Bronze: UNS C37700, UNS C92200, UNS C83600, UNS C84800…Surface Coating:ØENP ,ØChrome Plating,ØTungsten Carbide,ØChrome Carbide,ØStellite,ØInconelA.E.A manufactures single balls or kit Seats and Ball from 1/2 up to 60 Inches.

INSPECTIONWe are able to provide any kind of NDE ( Non-Destructive Examination) tests required.PT (Penetrant test) UT (Ultrasonic test) PMI (Positive material Identification) MT (Magnetic test) Thickness test (for cladding, plating or coating) Alcohol Test (for MTM kits) Corrosion Test

All the inspection and testing results of the materials and valves are registered in our quality system to support ongoing quality control efforts. All record of valve series numbers, inspection/testing procedure and results, operator information, are traceable.

You may also like

Send inquiry

Send now