Powderrange 718 (15-45um) Inconel 718 Argon Am (15-53um)

PowderRange 718 (15-45um)Inconel 718 Argon AM (15-53um) Product introduction GH4169 (IN718) is a precipitation strengthe;

Basic Info

| Model NO. | GH4169 |

| HS Code | 7504002000 |

| Production Capacity | 1000000kg |

Product Description

PowderRange 718 (15-45um)Inconel 718 Argon AM (15-53um)Product introduction

GH4169 (IN718) is a precipitation strengthened nickel base superalloy, which has good comprehensive properties in the temperature range of -253 ~ 650 ºC. The yield strength below 650 ºC ranks first among deformed superalloys, and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, and good processing properties

Chemical composition of powder (wt.%)

| Element | C | Cr | Ni | Co | Mo | Al |

| Content range | ≤0.08 | 17.0-21.0 | 50.0-55.0 | ≤ 1.00 | 2.80-3.30 | 0.30-0.70 |

| Element | Ti | Nb | B | Mg | Mn | Si |

| Content range | 0.65-1.15 | 4.75-5.5 | ≤0.006 | ≤0.01 | ≤0.35 | ≤0.35 |

| Element | P | S | Cu | N | O | Fe |

| Content range | ≤0.015 | ≤0.015 | ≤0.30 | ≤0.02 | ≤0.025 | Bal. |

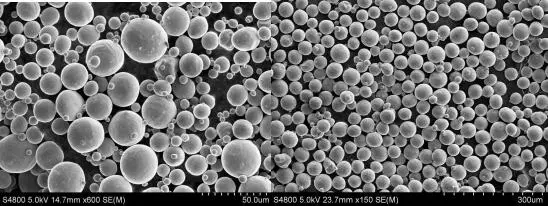

Powder electron microscope (sphericity 0.9)

Physical properties of powder

| Project | Granularity | Mobility | Bulk density | Tamping density | ||

| Range | D10 | D50 | D90 | ≤18s/50g | ≥4.2g/cm³ | ≥4.8g/cm³ |

| 16-24um | 32-40um | 45-53um | ||||

Powder printing performance

| Heat treated performance | |||

| tensile strength(Mpa) | yield strength(Mpa | hardness HRC/HV | Elongation |

| 1100±70 | 800±70 | 300±20 HV5/15 | 24±4 |

| Print state performance | |||

| Tensile strength(Mpa) | Yield strength(Mpa) | Hardness HRC/HV | Elongation |

| 1350± 100 | n/a | 430±30 HV5/15 | 16±4 |

You may also like

Send inquiry

Send now