Powderrange 625 (15-45um) Inconel 625 Argon Am (15-53um)

PowderRange 625 (15-45um)Inconel 625 Argon AM (15-53um) Product introduction Gh3625 (in625) alloy is a solution strength;

Basic Info

| Model NO. | GH3625 |

| Application | 3D Printing |

| Standard | JIS, GB, DIN, BS, ASTM, AISI |

| HS Code | 7504002000 |

| Production Capacity | 1000000kg |

Product Description

PowderRange 625 (15-45um)Inconel 625 Argon AM (15-53um)

Product introduction

Gh3625 (in625) alloy is a solution strengthened nickel base deformed superalloy with molybdenum and niobium as the main strengthening element. It has excellent corrosion resistance and oxidation resistance. It has good tensile and fatigue properties from low temperature to 980 ºC, and is resistant to stress corrosion in salt spray atmosphere. Therefore, it can be widely used in manufacturing aircraft

Aero engine parts, aerospace structural components and chemical equipment.

Chemical composition of powder (wt.%)

| Element | C | Cr | Ni | Co | Mo | Al | Ti |

| Content range | ≤0.10 | 20.0-23.0 | Bal. | ≤ 1.00 | 8.00-10.00 | ≤0.40 | ≤0.40 |

| Element | S | Cu | Mn | P | N | O | / |

| Content range | ≤0.015 | ≤0.070 | ≤0.50 | ≤0.015 | ≤0.04 | ≤0.05 | / |

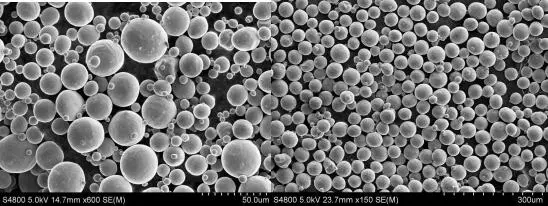

Powder electron microscope (sphericity 0.9)

Physical properties of powder

| Project | Granularity | Mobility | Bulk density | Tamping density | ||

| Range | D10 | D50 | D90 | ≤20s/50g | ≥4.2g/cm³ | ≥4.6g/cm³ |

| 16-23um | 30-40um | 45-53um | ||||

Powder printing performance

| Heat treated performance | |||

| tensile strength(Mpa) | yield strength(Mpa | hardness HRC/HV | Elongation |

| 1000±70 | 730±70 | 270± 10 HV5/15 | 35±5 |

| Print state performance | |||

| Tensile strength(Mpa) | Yield strength(Mpa) | Hardness HRC/HV | Elongation |

| 1050±70 | 700±70 | n/a | 35±5 |

You may also like

Send inquiry

Send now